Want to improve your metalworking? Just use abrasive cutting discs! These strong tools may help you make accurate cuts and flawless finishes on various materials, whether a beginner or a master. However, various sorts and sizes make it difficult to choose. The blog put together the Ultimate Guide to Abrasive Cutting Discs to help you choose the best disc for your project, use it safely and efficiently, and get outstanding results every time! Let’s start—grab your safety gear and leap in!

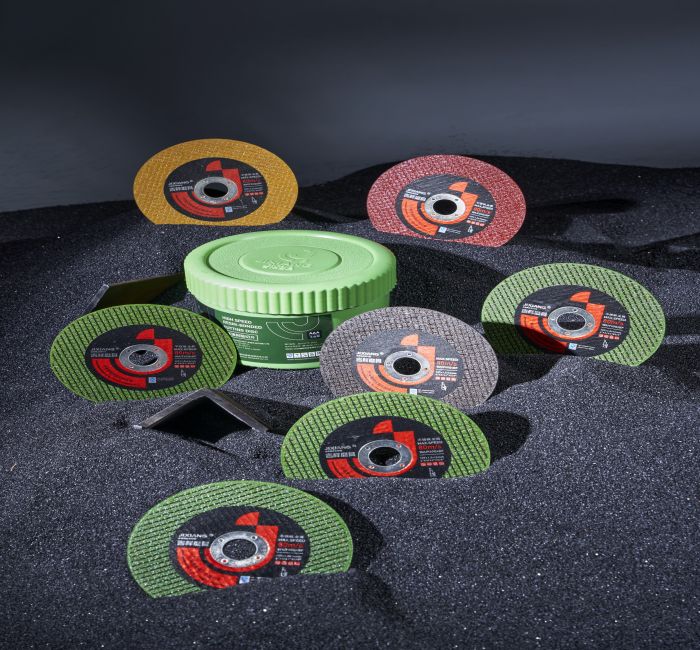

Types of abrasive cutting discs

Different abrasive cutting discs have pros and cons. The three main kinds are:

- Sandpaper discs. Small, paper-like sheets are attached to a backing disc. Small sheets cut swiftly and readily because of their high grit (particle size). Sandpaper discs are less durable and leave stains on finished surfaces.

- Diamond-coated abrasive discs. These diamond-coated discs carve thousands of minute holes as they are dragged over the material. They have a clean finish and little drag, perfect for precise tasks like engraving. However, they are more costly and need particular maintenance, including lubrication.

- Ceramic knives. Ceramic blades have small teeth or lobes. These teeth or lobes grasp the material and cut it effortlessly. Ceramic blades are sharp and don’t damage finishes like sandpaper or diamond-coated abrasives.

Benefits of using abrasive cutting discs

Abrasive cutting discs assist users and producers. They cut materials swiftly and correctly, saving time and money. These discs’ sharper edges further minimize material use.

Cutting discs let users cut materials quickly. They help remove significant volumes of stuff fast. Cutting discs may improve manufacturing efficiency. These discs quickly cut through numerous layers of cloth, saving time and money.

Conclusion

Thanks for reading the abrasive cutting disc instructions! Hopefully it helped you understand the various disc kinds and what they can achieve for your woodworking project. The information should help woodworkers of all levels.

Leave a comment